Performance, security and cost, the 3 major challenges for the cold chain pharmaceutical logistics

Performance, cost, risks: choose security

Unsurprisingly, the three priorities for pharmaceutical supply chain logistics managers are performance, optimisation of costs and risk-reduction.

These challenges are all the more important when the logistics of pharmaceutical products is carried out via the cold chain.

The increasing number of links involved in the supply chain and the successive methods of storage and transport result in an inevitable lack of visibility across the entire pharmaceutical supply chain.

Although preventing risks throughout the medicine supply chain is impossible, protecting shipments makes it possible to have greater control of the medicine supply chain, reduce the risks and fundamentally lower the direct and indirect costs. It is with this in mind that Sofrigam’s expert engineers in the pharmaceutical chain have developed the new range of insulated Pallet Shippers.

Optimise your logistics costs and protect your shipments

Initial Pallet Shippers developed by Sofrigam have one aim: to offer containers that optimise your logistical costs and protect your shipments thanks to high-performance temperature control.

Since their size can be adapted to US and EU pallets, as well as PAG and PMC platforms for air freight, the Initial pallet shippers range is tailor-made to optimise your logistics. Delivered pre-assembled or flat-packed, reusable up to 5 times and highly optimised for an excellent external size/payload ratio, essentially sums up the benefits of this new range of packaging solutions.

Highly robust, the container has been tested under actual transport conditions, on successive round trips from France – United States.

Number of assembled and flat-packed Sofrigam QPMC Pallet Shippers in one lorry.

- Protect your shipments

The most challenging logistical circuits can include up to 15 to 20 different logistical steps between successive transportation, storage, transit, etc. not including the successive steps of loading and unloading. These all represent temperature variations and risks of breaks in the cold chain. Choosing a high-performance insulated packaging solution overcomes these risks. The Sofrigam Pallet Shipper guarantees constant temperatures for up to 120 hours under the international air freight profile ISTA 7D*. Given that preparation of the insulated container is a step that should not be ignored, the Sofrigam Pallet Shipper is risk-free: once assembled, the products are loaded directly into the container with the eutectic plates. As a result, exposure of the products outside of the refrigerated range is minimised.

- Reduce your logistics costs

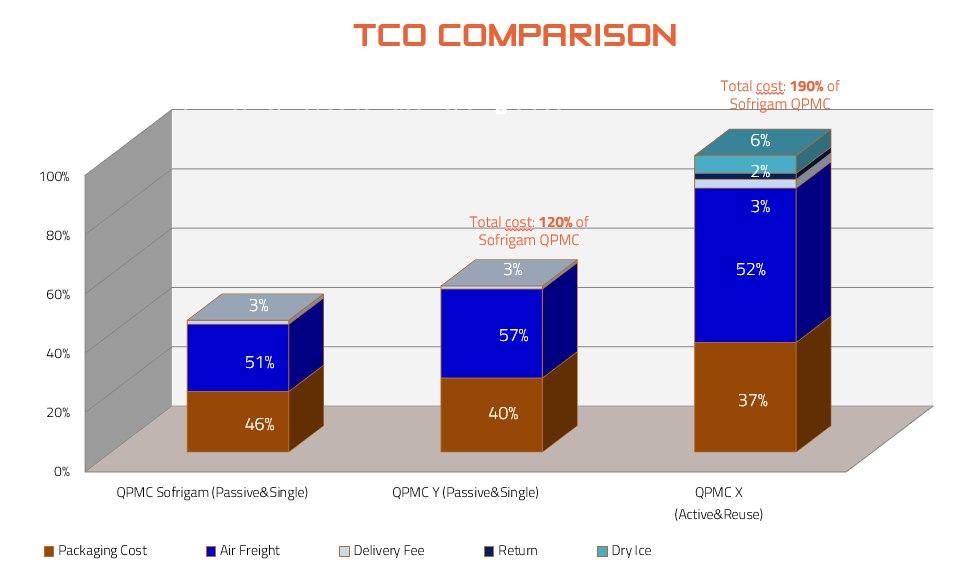

The Sofrigam Pallet Shipper has been designed to lower the TCO of your cold chain logistics. How? By optimising the payload of the packaging solution, reducing its weight and facilitating its assembly and preparation. 46% of the total cost of the packaging solution is devoted to the purchase of the packaging, and 51% corresponds to air freight costs. The result is a container with the best TCO on the market for optimising your total logistical costs.

Total cost comparison (TCO) of Quarter PMC insulated containers

-

Minimise your carbon footprint

Flat-packed, reusable up to 5 times, light, optimised by its external size / internal size ratio, this Pallet Shipper will support you in your approach to protecting the environment. Delivering more products in one container is not only economical but it is also good for the planet!

Do you want to optimise and protect the transport of cold chain pharmaceutical products? Our container can be fully adapted to your logistical constraints. Contact our experts!

* Packaging tested and qualified by the Ater Métrologie thermal testing laboratory. Temperature charts and the qualification dossier are available on request.