News

Thematic studies

Insulated boxes with dry ice to secure the cold chain for Covid-19 vaccines

The global health crisis caused by the Covid-19 pandemic has accelerated research to develop an effective vaccine against this SARS-CoV-2 virus. All heat-sensitive vaccines have storage temperature ranges managed by using available active or passive cold production means, but the first Covid-19 vaccines developed must be stored and transported between -90 and -60 °C. The eutectic plates traditionally used for the -25/-15 °C range cannot meet this need, because they do not offer melting temperatures close to -70 °C. With a sublimation enthalpy of 573 kJ.kg-1 (25,2 kJ.mol-1) at -78.5 °C, dry ice is the best way to secure the cold chain of these vaccines. In this article, we analyse standalone solutions of insulated boxes using dry ice as a cold source, allowing to transport safety these Covid-19 vaccines between -90 °C and -60 °C. The performance of the solution and the necessary amount of dry ice depend on the quality of the thermal insulation, the size of the box, the required cooling capacity (autonomy) and the ambient temperature.

Insulated boxes, designed for the transport of vaccines and heat-sensitive health products in general, are equipped with a cold source to compensate for thermal exchanges with the outside. Aqueous eutectic solutions and other phase-change materials (paraffins, fatty acids and hydrated salts) are used for the temperature ranges +2/+8 °C, +15/+25 °C, -25/-15 °C and other specific ranges. These materials cover temperatures ranges from -30 °C to +40 °C with acceptable performances. Dry ice is used in insulated boxes for temperature ranges below -30 °C, more particularly between -90 °C and -60 °C.

Thermal storage by dry ice

Carbon dioxide in the solid form, called "dry ice", is obtained by the solidification of liquid CO2 (carbon dioxide snow). The carbon dioxide snow is then compressed to obtain dry ice.

Dry ice is used as a cold source in insulated shipping boxes to transport thermosensitive products at very low temperatures. Depending on the maximum temperature and preparation means available, it is used in:

- Pellets of approximately 3 mm diameter.

- Sticks of approximately 16 mm long

- Blocks of different sizes

With a sublimation enthalpy of 573 kJ.kg-1 (25.2 kJ.mol-1) at -78.5 °C, dry ice compensates for the heat exchanged between the inside and outside of the insulated box by sublimination without leaving any residue.

The energy Q [J] stored in dry ice is given by equation 1.

Q = M • Ls (1)

M: dry ice mass [kg]

Ls: sublimation enthalpy of dry ice [J.kg-1]

The energy Q [J] stored by dry ice must be at least equal to that exchanged between the interior and the exterior of the insulated box and given by equation 2.

Q = K • Sm • (Te - Ti) • t (2)

K: overall heat transfer coefficient of the insulated box [W.m-1.K-1]

Sm: Geometric mean of the interior and exterior surfaces of the insulated box [m2]

Te - Ti: The difference between the interior and exterior temperature of the box [°C]

t: time (effective cooling capacity) [s]

Thermal insulation material and effective cooling capacity of insulated boxes

The quantity of dry ice necessary in an insulated packaging box depends on several factors. The principal parameters are:

- The overall heat transfer coefficient K of the insulated box;

- The exterior temperature profile;

- The duration of the logistical circuit (effective cooling capacity);

- The upper limit of the temperature range of the product to be transported.

The necessary mass of dry ice must be increased to have a sufficient quantity on arrival to maintain the temperature below the required limit. The coefficient of increase depends on the quality of the insulating material, the required effective cooling capacity, the ambient temperature and the required maximum storage temperature. The dry ice should also completely cover all six surfaces of the products, which implies a minimum effective cooling capacity of 48 h for large volumes and 24 h for small volumes.

In this part, we analyse the impact of the insulating material quality on the performance of insulated boxes using dry ice.

- By fixing the external dimensions and varying the thickness of the insulating material (internal V).

- By fixing the internal dimensions and varying the thickness of the insulating material (external V).

PU and PS at constant external volume

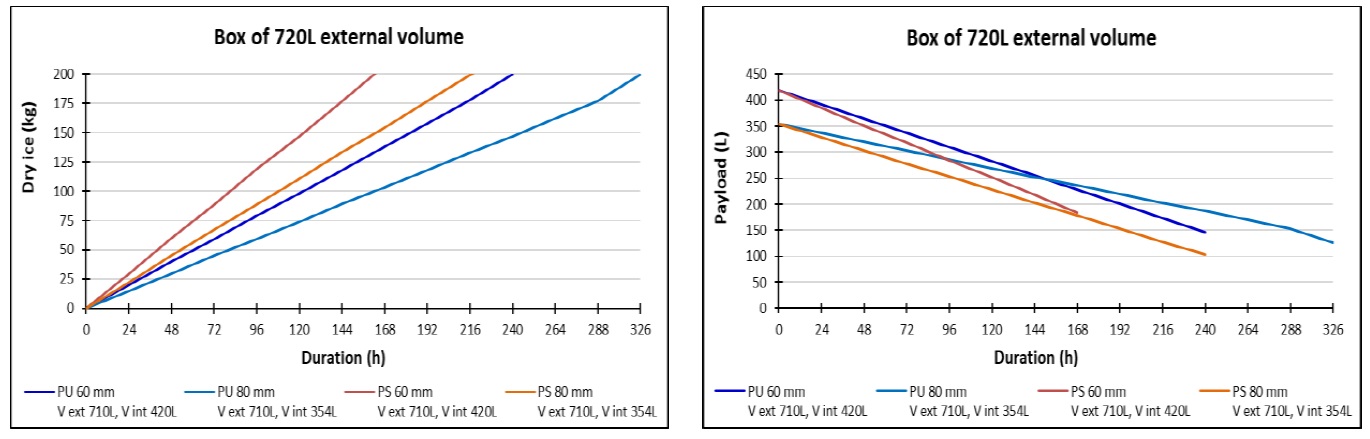

By fixing the external dimensions of the insulating box, we analyze the variation of the mass of dry ice necessary according to the required effective cooling capacity, by type and thickness of insulating material. We have chosen a box with a European pallet base, of external dimensions 1200 x 800 x 740 mm, i.e. an external volume of 710 liters. We compare the performance of polyurethane and polystyrene boxes of thicknesses of 60 mm and 80 mm.

Figure 1 shows the variation of the dry ice mass and the available payload for the products as a function of the effective cooling capacity offered by the solution. The mass presented by the curves must be increased as a function of the parameters mentioned above. We limit ourselves to the maximum amount of 200 kg of solid CO2 authorized per box for air transport.

At equal dimensions and thicknesses, the polyurethane (PU) boxes perform approximately 50% better than those of polystyrene (PS).

- For the same thickness and given effective cooling capacity, polystyrene boxes require 1.5 times as much dry ice as those of polyurethane. Conversely, for the same mass of dry ice, the effective cooling capacity ratio is 1.5 in favor of polyurethane boxes.

- With the maximum amount of dry ice authorized per box in an airplane:

> The effective cooling capacity for 60 mm PU is approximately 192 h to 216 h (8 to 9 days) versus approximately 120 h to 144 h (5 to 6 days) for the PS box.

> The effective cooling capacity for 80 mm PU is approximately 264 h to 288 h (11 to 12 days) versus approximately 192 h to 216 h (8 to 9 days) for the PS box.

- The dry ice must cover all 6 surfaces of the product, which requires a minimum quantity and consequently a minimum effective cooling capacity of 24 to 48 hours for PS boxes and 48 to 72 hours for PU boxes.

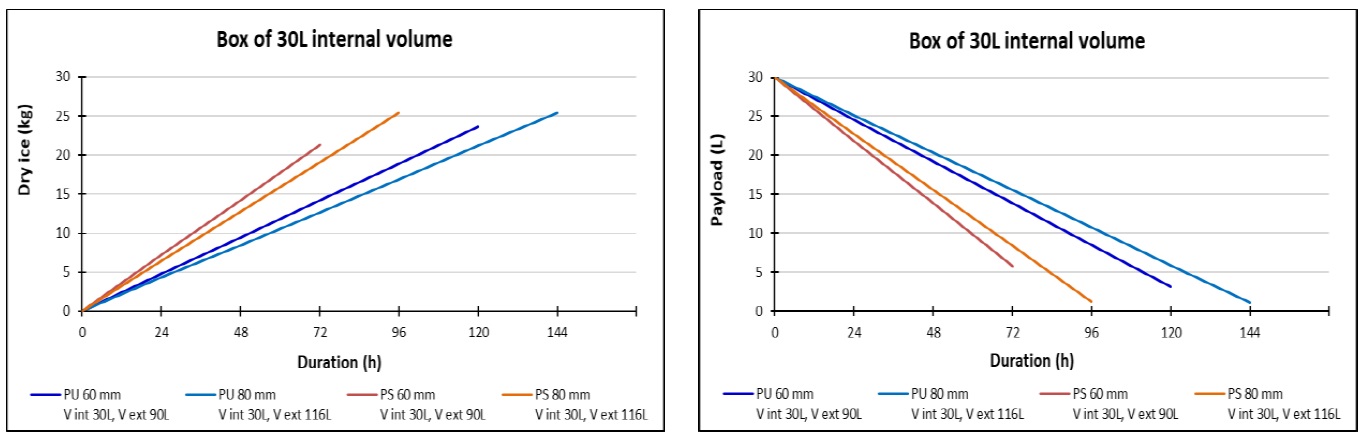

PU and PS at constant internal volume

By fixing the internal dimensions of the insulating packaging, we analyze the variation of the mass of dry ice necessary according to the required effective cooling capacity, by type and thickness of insulating material. For this analysis, we chose a box with an internal volume of 30 liters. The external volume varies according to the thickness of the walls. We compare the performances of boxes with the same dimensions in polyurethane and polystyrene of thickness of 60 mm and 80 mm. The PU and PS boxes will then be compared with a box of vacuum insulated panels (VIP) encapsulated in PU of a total thickness of 30 mm (PU+VIP+PU: 5+20+5 mm).

It is important to note that non-encapsulated VIP is not resistant to dry ice. The film is damaged at very low temperature, thus losing the thermal advantage of VIP.

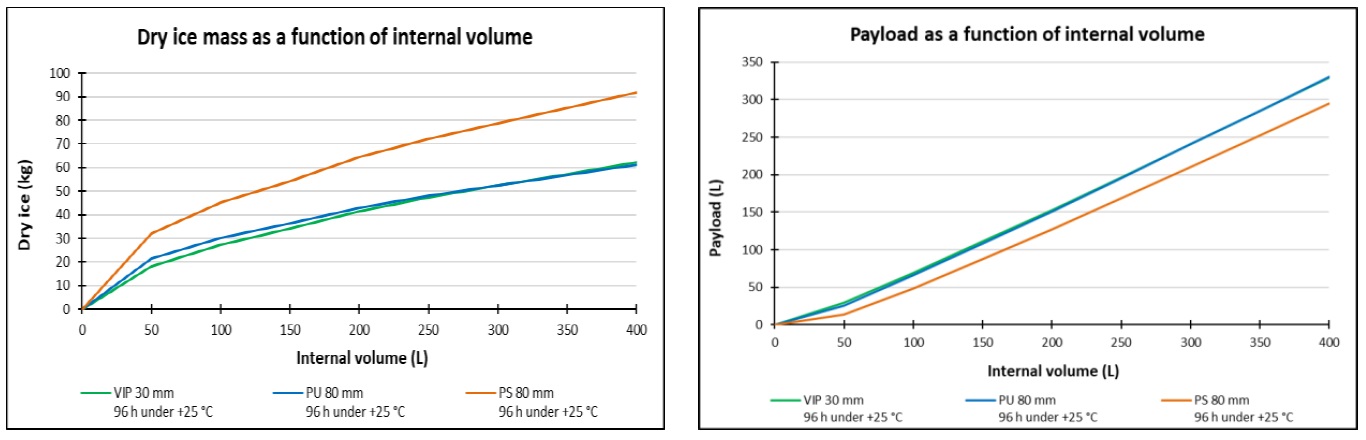

Figure 2 shows the variation of the dry ice mass and the available payload for the products as a function of the effective cooling capacity offered by the solution.

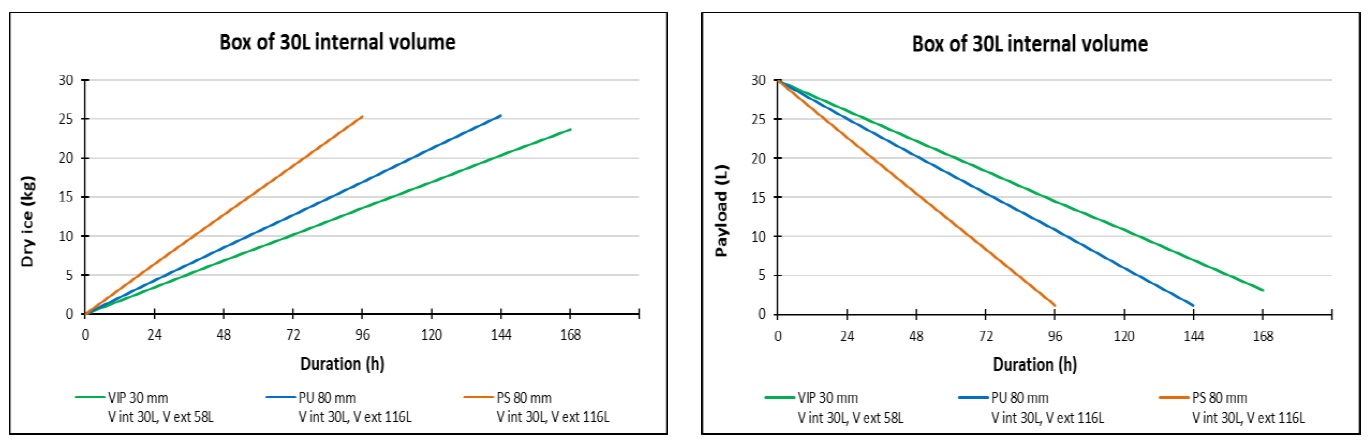

Figure 3 shows the variation of the dry ice mass and available payload, as a function of the effective cooling capacity offered by the solutions in 80 mm PU and PS and that of 30 mm VIP.

The mass presented by the curves must be increased as a function of the parameters mentioned above. We will limit ourselves to the maximum quantity of dry ice that corresponds to the total internal volume of the box (30 L).

As for the previous case, at equal dimensions and thicknesses, polyurethane cold chain boxes perform approximately 50% better than those made of polystyrene.

- For the same thickness and given effective cooling capacity, polystyrene boxes require 1.5 times as much dry ice as those of polyurethane. Conversely, for the same mass of dry ice, the effective cooling capacity ratio is 1.5 in favor of polyurethane boxes.

- Depending on the quality and thickness of the insulating material, a maximum effective cooling capacity is determined, from which the payload will be negligible:

o 60 to 72 hours for the 60 mm PS box

o 72 to 84 hours for the 80 mm PS box

o 96 to 114 hours for the 60 mm PU box

o 114 to 126 hours for the 80 mm PU box

- The dry ice must cover all 6 surfaces of the product, which requires a minimum quantity and consequently a minimum effective cooling capacity. For boxes of 30-liter internal volume, the minimum effective cooling capacity is approximately 24 hours for PS boxes and 48 hours for PU boxes.

The curves presented for Figure 3 compare the performances of 80 mm PS boxes, 80 mm PU boxes and boxes with 20 mm VIP encapsulated in 5-mm PU (PU+VIP+PU: 5+20+5 mm). The boxes have the same internal dimensions.

- For the same internal volume of 30 L and for a given effective cooling capacity, the PS box requires 1.5 times as much dry ice as the PU one, and the PU one requires 1.25 times as much relative to the VIP box. Conversely, for the same mass of CO2, the effective cooling capacity ratio is respectively 1.5 and 1.25.

- In addition to reducing the thickness, the maximum effective cooling capacity, from which the payload will be negligible is increased from a mean of 78 hours for 80 mm PS and 120 hours for 80 mm PU to 150 h for 30 mm VIP+PU.

- For the quantity of dry ice covering all 6 surfaces, the minimum effective cooling capacity offered by VIP+PU is approximately 72 hours.

PU and VIP at constant internal volume

Figure 4 shows the variation of the dry ice mass and payload (available) as a function of the internal volume for 80 mm PU and PS, as well as for 30 mm VIP+PU. The curves correspond to an effective cooling capacity of 96 hours at +25 °C.

According to these curves, the performances of the PU and encapsulated VIP (VIP+PU) boxes are better than those of the PS boxes.

- The ratio of the necessary mass of dry ice, between PS and PU, increases as a function of the internal volume of the box. PU boxes therefore offer greater available volumes than those of PS boxes.

- For the largest volumes, the performances of 30 mm VIP+PU are equivalent overall to those of 80 mm PU.

Thermal performances tests

We use PU and encapsulated VIP to perform the thermal performance tests on insulated boxes with dry ice.

Boxes of 30 L internal volume

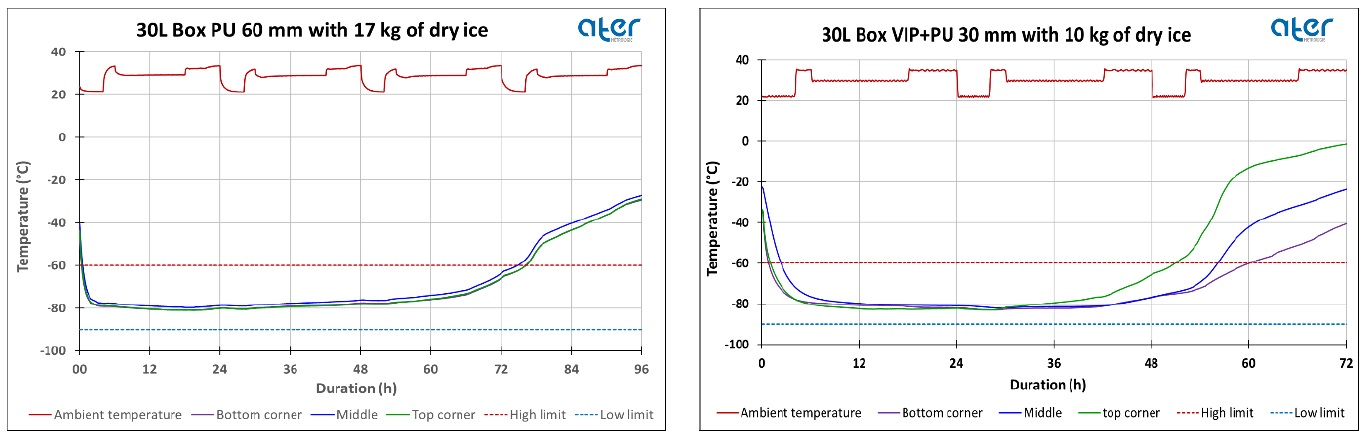

Thermal performance tests were performed on insulated boxes with an internal volume of 30L, in 60 mm PU and 30 mm encapsulated VIP (VIP+PU). Introduced into the boxes at -20 °C, the products are cooled and then stored below -60 °C with dry ice.

Figure 5 shows the effective cooling capacity of the 60 mm PU box with 17 kg of dry ice, under the ISTA 7D hot profile with a mean temperature of +30.5 °C.

Figure 6 shows the effective cooling capacity of the 30 mm encapsulated VIP (VIP+PU) box with 10 kg of dry ice, under the same ISTA 7D hot temperature profile.

The results of the performance tests show the capacity of both boxes to secure the Covid-19 vaccine cold chain at very low temperatures.

- With 17 kg of dry ice, the 60 mm PU box allows maintaining vaccines between -90 °C and -60 °C for 75 hours, under a very hot temperature profile.

- With 10 kg of dry ice, the 30 mm VIP+PU box allows storing vaccines between -90 °C and -60 °C for 51 hours, under the same temperature profile. With 17 kg of dry ice, its effective cooling capacity (duration) will be increased to 120 hours.

- The effective cooling capacity will be increased by introducing the products at -70 °C.

- The effective cooling capacity of both boxes can be improved by increasing the insulating material thickness or the quantity of dry ice.

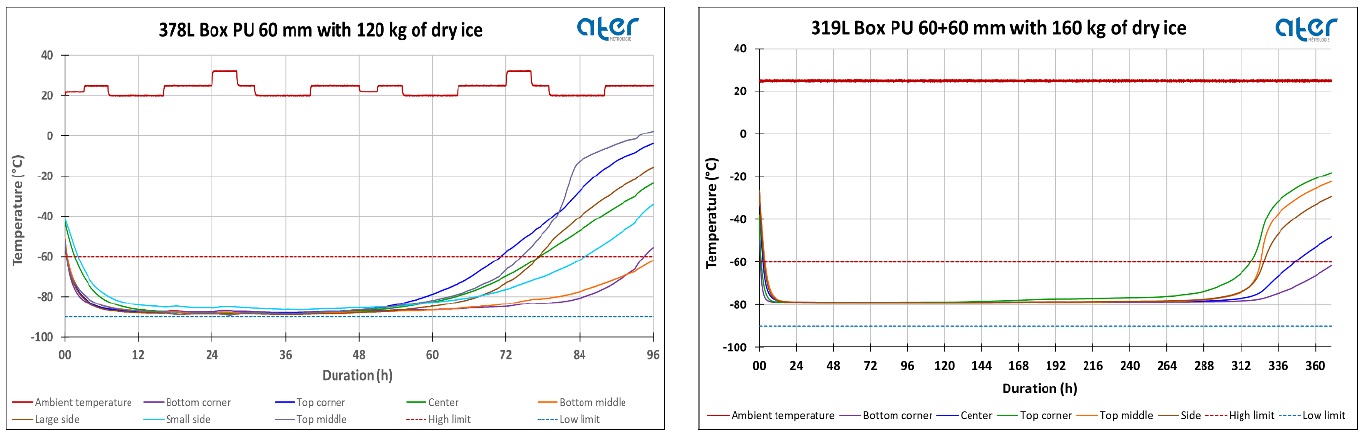

Large volume pallet shippers

Thermal performance tests were performed on large-volume insulated shippers with a pallet base. The products are introduced into the shippers at -20 °C.

Figure 7 shows the effective cooling capacity of the 60 mm PU shipper, with internal volume of 378 L, with 120 kg of dry ice, under the ST-96-b hot profile (mean temperature of +23.5 °C).

Figure 8 shows the effective cooling capacity of a 60+60 mm PU double belt shipper, of an internal volume of 319 L, with 160 kg of dry ice, at a constant ambient temperature of +25 °C.

The results of the performance tests show that large volume shippers allow securing the Covid-19 vaccine cold chain at very low temperatures. They offer superior effective cooling capacities to those of small and medium boxes, able to reach 15 days.

- With 120 kg of dry ice, the 319 L insulated pallet shipper of 60 mm PU allows storing vaccines between -90 °C and -60 °C for 72 hours, under a standard ST-96-b profile of standard NF S 99-700. This effective cooling capacity can be extended by increasing the mass of dry ice within the limit of 200 kg.

- With 160 kg of dry ice, the 319 L double belt insulated pallet shipper of 60+60 mm PU allows storing the vaccines between -90 °C and -60 °C for at least 13 days (318 hours), at a constant ambient temperature of +25 °C. This effective cooling capacity can be extended by increasing the dry ice mass within the limit of 200 kg.

Conclusions

Insulated boxes using dry ice as cold sources permit transporting Covid-19 vaccines between -90 °C and -60 °C. Depending on the insulating material used, these solutions offer effective cooling capacities ranging from 48 hours to more than 10 days. At identical dimensions, the performances of polyurethane are 1.5 times those of polystyrene. For the same effective cooling capacity, the quantity of dry ice necessary for a PS box is 1.5 times greater than that made of PU. Conversely, for the same mass of dry ice, the payload is 1.5 times greater for the PU box. Vacuum insulated panels (VIP) encapsulated in PU reduce the thickness and, therefore, the volume transported. 20 mm VIP encapsulated with a 5 mm layer of PU (total thickness of 30 mm) is equivalent overall to 80 mm PU. Non-encapsulated VIP alone is not compatible with dry ice since the envelope (film) protecting the vacuum is not resistant to very low temperatures.