#EliteWolrdTour: the round-the-world tour of a package

Elite, a high performance temperature-controlled packaging solution

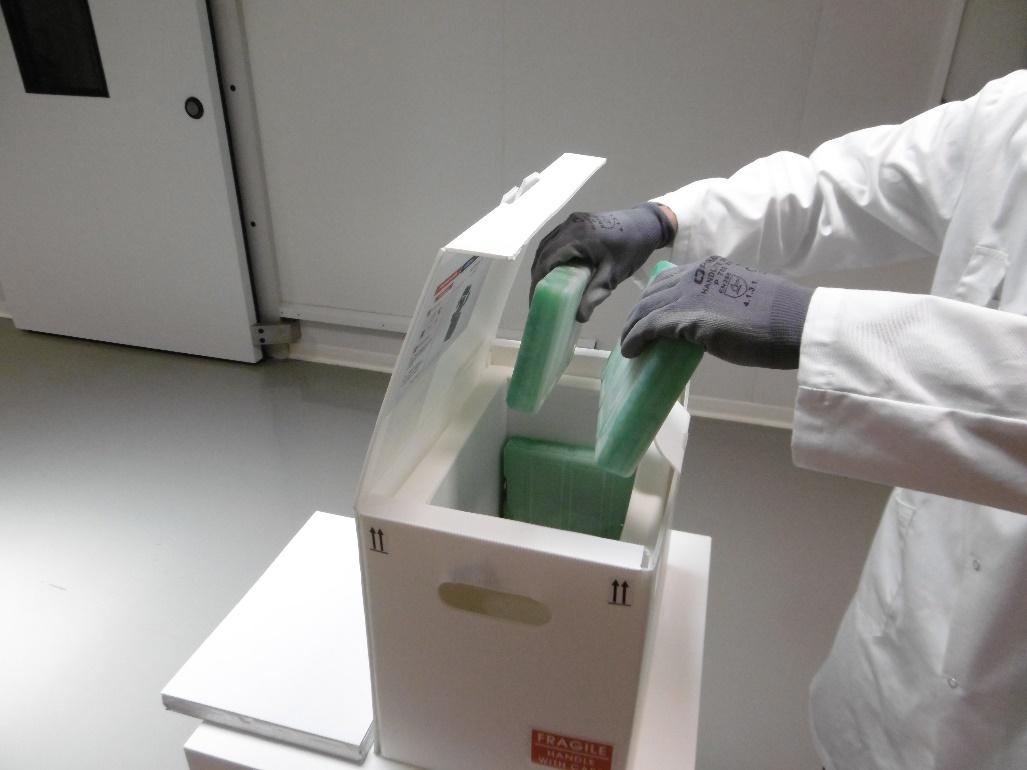

The Elite reusable insulated box in preparation for its world tour

Elite is a range of reusable refrigerated boxes designed by Sofrigam to ensure the transport of pharmaceutical products via the cold chain (+2/+8°C) for up to 168 hours*! These insulated packaging solutions are made from high performance and highly resistant materials to ensure a perfectly maintained constant temperature and to guarantee a number of uses. The box is made from a very high performance insulating material: VIP. This material provides 3 times greater insulation than polyurethane. The external packaging is made from polypropylene, a highly resistant, impermeable, washable material. The PVC internal lining allows the area in contact with the pharmaceutical products to be washed and disinfected.

Elite is a refrigerated box that is easy-to-use because it is prepared in the same way whatever the shipping season.

A journey under intense scrutiny!

Shipping of the Elite packaging solution from Sofrigam’s production plant in Arras, Hauts de France region

Equipped with a temperature recorder with integrated GPS, the Elite insulated box was shipped around the world in 13 days, passing through the United States, Canada and China to eventually return to France. The map below shows the journey undertaken by the packaging solution thanks to geo-tracking.

Journey of the insulated box during its world tour

The operation #EliteWorldTour was broadcast on Twitter, Facebook and Linkedin so that the journey of the Elite packaging solution could be followed in real time.

At each stage, the insulated box was carefully monitored: the temperature was systematically verified and the packaging solution unpacked to be checked by a quality control team. The condition of the external packaging, internal configurations and configuration of the insulating material, verification of the internal temperature and temperature recordings from the logger were all part of the control parameters.

Preparation of the Elite insulated box

The Elite insulated box was only authorised for reshipment if these control parameters did not reveal any shortcomings.

13 days and more than 28 000 km travelled

The Elite temperature-controlled packaging solution was shipped from France on 13 September to its first destination: our American subsidiary in Texas. Despite being repeatedly subjected to high temperatures (>+33°C – transportation in vehicles without air conditioning), the packaging solution maintained a constant temperature of between +2°C and +8°C and the journey took place without any problems over 48 hours. The box arrived in perfect condition. Following quality control and a change of eutectic plates in the packaging solution, the box was reshipped the next day to one of our partners in Canada!

Following its arrival in Vancouver, Canada on 18 September, the insulated packaging solution was still in good condition and the internal temperature remained constant at +2/+8°C, in spite of transport and storage phases in environments without air conditioning during which the box was subjected to temperatures above +30°C. The teams, which had frozen a set of eutectic plates beforehand, shipped it on the following day to China.

48 hours later, the Elite packaging solution arrived in China via the cold chain! Following quality control and temperature reading, the checking was conclusive! The packaging solution was subject to a ‘cold peak’ (the temperature dropped below +2°C) for a few hours at the start of the journey, due to poor preparation of the eutectic plates. The Elite temperature-controlled box returned to the Sofrigam production site in France on 26 September.

Shipping of the packaging solution from China to France

Almost 30 000 kilometres travelled over 13 days (312 hours) around the world with an average external temperature of +25°C: the Elite insulated box was subjected to a severe test! Even if it came back more grey than white, the insulated packaging solution withstood storage, transits, successive loading and unloading all while maintaining a perfectly stable internal temperature. Elite certainly met the challenge!

* Qualified packaging solution under the ISTA 7D summer and winter profile. Temperature recordings available on request.