How can you define the logistics profile of cold chain transportation?

Do you establish specifications in order to define your insulated packaging solution requirements? The logistics profile must be specifically defined to guarantee transported products are subject to cold chain transportation. Use our 3-stage method to define it.

The logistics profile governing insulated packaging solutions takes into consideration external environments.

The logistics profile takes into consideration environments external to the packing unit during transportation (temperatures, stages and durations). This affects the size, design and cost of your packing unit. In essence, the greater the heat intake/loss, the greater the PCM (phase-change material) quantity and therefore the thermal resistance of the package sides must be significant to guarantee the desired temperature range. The greater the climatic limitations, the higher the overall cost (TCO) of the solution.

Define the logistical circuit framework

Chronologically list all logistical stages to which the consignment is subjected, from departure to arrival of the package to the final destination. Apply a duration to each stage.

Add the estimated temperatures to each stage of the process

Indicate the average temperature bearing in mind the following parameters:

- average temperatures noted over the past 10 years,

- the season,

- average temperature for the day on which the logistical segment takes place.

Segments may be blocked (controlled, managed and guaranteed temperature), or open (dependent on the local external climatic conditions).

"The aim is to satisfy duration/temperature pairings throughout the entire consignment".

Cyryl Polkotycki, Engineer within the Design Office

With this example, the green segments are the open segments and blue are the closed segments. The yellow segments indicate the merchandise preparation and acceptance stages.

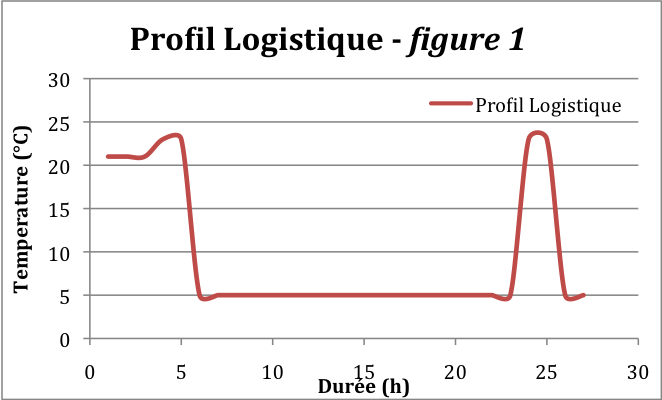

To complete tests within a climatic chamber, the logistical circuit is presented in the form of a curve.

This figure illustrates the logistics profile of the example provided above.

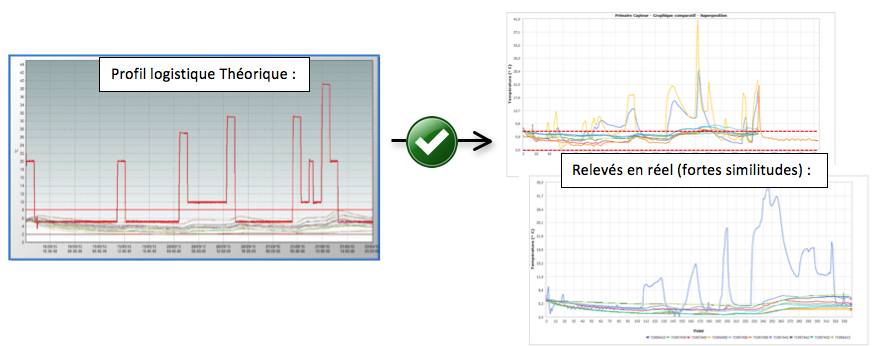

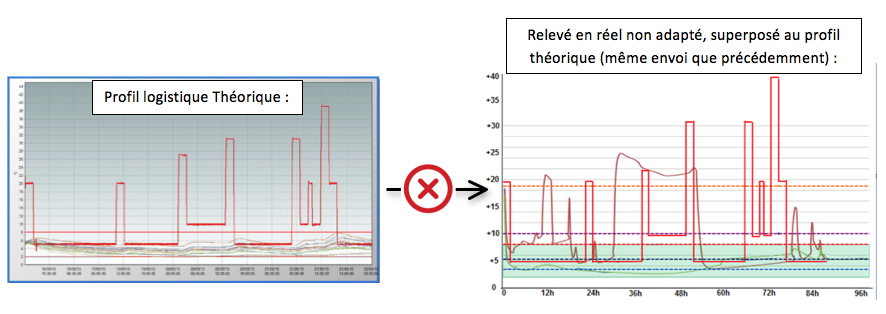

Check the compliance of the logistics profile against the temperatures noted in a real situation

Look out for correlation between the defined profile and the reality of the transportation. This allows you to work more closely with your suppliers and to achieve a durable and affordable insulated packaging solution.

"This last stage is often ignored (cost, analysis of data...) but it is recommended as it allows you to build up an idea of the sizing work and to ensure that all cost-saving technical tools have been deployed!"

Cyryl Polkotycki, Engineer within the Design Office

In this case, the genuine results are not far off the estimated theoretic profile.

In this case, the genuine results do not correspond with the estimated logistics profile.

Traps to be avoided

- Oversizing your insulated or refrigerated package. This is why it is important to follow the 3 stages described above.

- The selection of profiles which are too hot or too cold may affect the consignment logistics profile. This is erroneous, particularly with multiple configuration packages. In the case of a single configuration package, it is less significant, however it could increase the overall cost of the solution...

"To use a packing unit designed to satisfy your requirements as closely as possible, study the logistics profile which the packing unit has to endure! Sofrigam campaigns for this approach which serves to reduce oversizing and unnecessary costs to clients. We can advise you when establishing specifications, and with improving an existing solution during the operational stage."

Cyryl Polkotycki, Engineer within the Design Office

Where the definition and management of the consignment logistical circuit is important, the selection between mono and multi-configuration is just as important.