Mono-configuration or multi-configuration insulated container?

In a previous article, we detailed the parameters to be considered when determining the size of insulated temperature controlled packaging box container. Volume of the product to be transported, internal temperature range, period of storage and logistical constraints: once these criteria have been defined, they enable engineers to create an insulated container that fully satisfies your requirements.

However, in addition to these criteria, another factor has an overriding impact on the design of the container, namely the type of configuration of the container.

Insulated container: which type of configuration?

Two types of configuration influence the overall composition of the container.

Jérémy Clerfeuille, Engineer and Design Office Manager at Sofrigam, explains the advantages of each of these configurations.

The mono-configuration insulated packaging solution: simplicity and security

A mono-configuration packaging has just one preparation protocol, regardless of the season during which it is dispatched or its destination.

This robust solution:

- reduces the possibility of errors during preparation (only one protocol to be applied);

- benefits from significant thermal inertia;

- reduces the risk of temperature fluctuations;

- features greater stability and consistent internal temperatures, a fundamental aspect of compliance with the cold chain for heat-sensitive products.

If you need greater security for the transported products, choose from the mono-configuration product range.

The multi-configuration insulated packaging solution: optimised transportation

A multi-configuration container has several preparation protocols: these may vary according to the destination and/or the season. The factors that distinguish one configuration from another are usually the quantity and temperature at which the eutectic gels are inserted, as well as the thickness of the thermal separators.

The advantages of this configuration include:

- quick loading;

- an improved ratio between external volume and net volume (payload);

- optimised weight.

If you want to optimise technical properties such as weight, overall size and preparation time when transporting your products, opt for the multi-configuration product range.

Case study: transporting medicines in a multi-configuration container

A pharmaceuticals company asked us to devise a multi-configuration temperature controlled packaging solution to replace the mono-configuration packaging solution it was currently using.

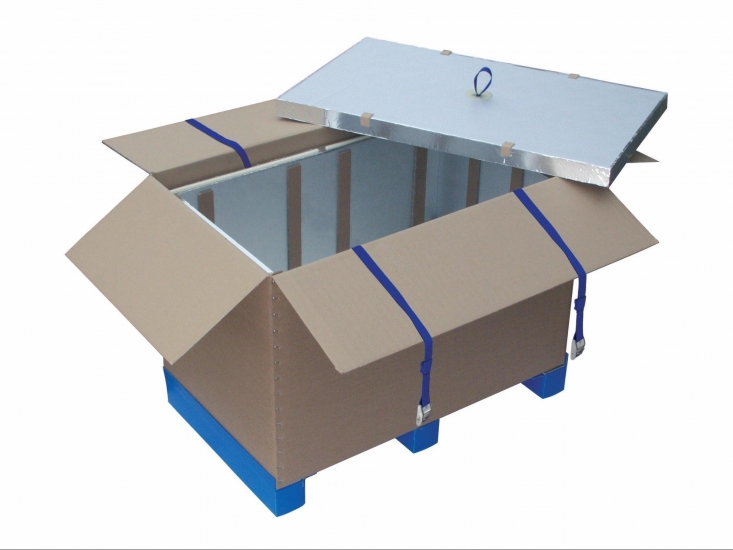

The mono-configuration insulated container used initially

Preparing the multi-configuration packaging solution is more constraining but the insulated container requires fewer eutectic gel packs.

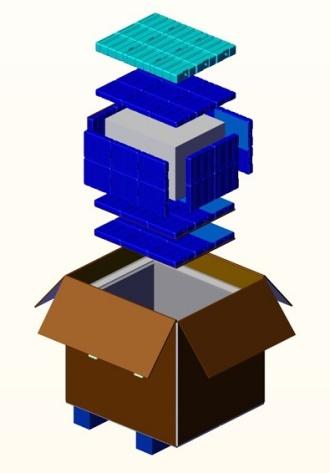

Summer configuration

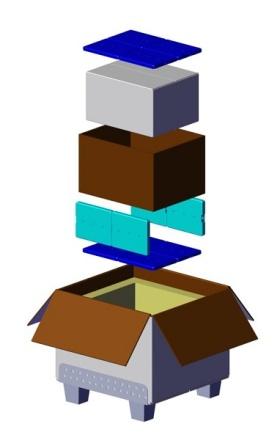

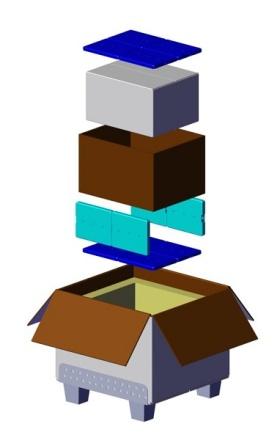

Winter configuration

Proposed multi-configuration insulated packaging solution

As a result, more products can be transported, the weight of the container is reduced and transport costs are optimised.

These two types of design offer different benefits. Choose the type of configuration for your insulated containers not only on the basis of the criteria indicated above but also according to the degree of expertise with the cold chain throughout the logistics network and the destinations to which the products are to be dispatched.

Do not hesitate to get in touch with us if you have any questions concerning the design of a made-to-measure insulated container.