Thematic studies

News

Case studies

Polyurethane : the ecologically sound insulating material

Polyurethane, used everywhere in the construction industry and in nearly every aspect of our daily lives, is also the material of choice for insulated shipping packaging. Sofrigam is placing the challenges of sustainable development at the core of its strategy and the Polyurethane is a cornerstone of Sofrigam’s environmental policy. Let us take a moment to explain why.

The least energy-intensive of all the insulating materials

The manufacture of polyurethane requires less than 0.1% of the oil consumed around the world and its many properties yield economies up to 100 times greater. In addition to being one of the least energy-intensive insulating materials in factory manufacturing, the service life of polyurethane is longer than that of other insulating materials.

A material that is both light and efficient

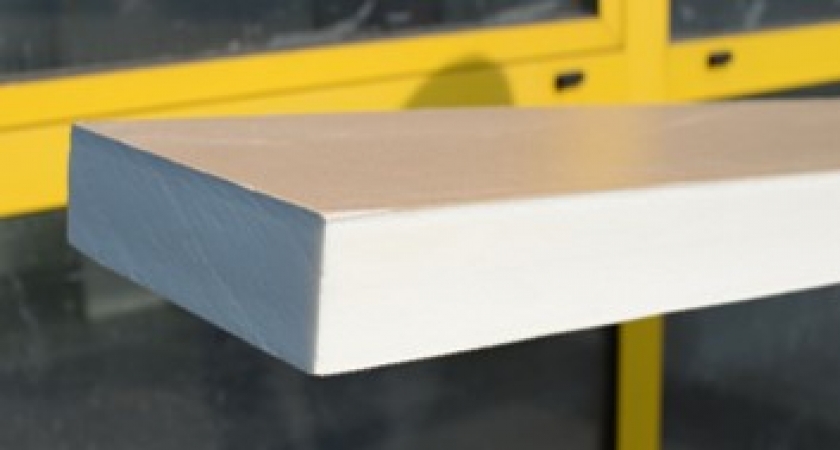

Polyurethane is both thinner and more efficient than other types of insulating material. This reduces the volume of the insulating material required. As a result, the manufacture of insulated containers consumes less energy and they are lighter to transport. This yields significant energy savings!

Furthermore, the same applies to the motor industry: polyurethane is used to reduce the weight of vehicles and, in turn, to reduce fuel consumption and CO2 emissions.

Polyurethane can be recycled

Sofrigam has opted for an efficient insulating material that will also help to save the planet. Here are 3 of the recycling solutions we have put in place:

- Recycling in the construction industry as insulating material: the polyurethane panels used in insulated pallet shippers are retrieved and sold. Polyurethane insulation 1.6 cm thick is just as effective as a concrete wall 1.34 metres thick: a good way to save on heating costs!

- Crushing and recycling in cement works: the polyurethane panels from cooling boxes are crushed and reused in cement works. By mixing the cement with particles of polyurethane, the resultant cement is lighter in weight and has improved insulating properties. These solutions for recycling polyurethane are being used more and more in the construction of dams and dykes.

- Energy conservation through incineration: waste polyurethane is incinerated in a clean manner, with pollutants being filtered out. The combustion process generates energy: the energy produced by incinerating polyurethane over a period of 1 year can be equivalent to the annual consumption of electricity by a household with 4 occupants!

Sofrigam cold chain shipping packaging solutions, produced in the form of polyurethane panels, are used every day to transport thousands of vaccines, ophthalmic products, chemotherapy solutions and other heat sensitive medicines throughout the world. They maintain constant temperatures for up to 72 hours. Contact us to find out more.