Focus on reusable cold chain packaging

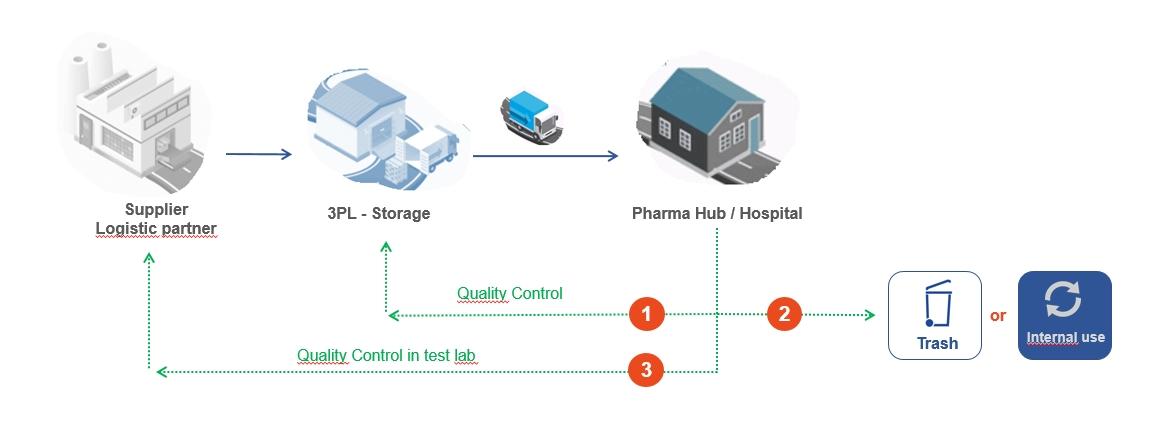

The different circuits for reusing insulated packaging

If at first glance, reusing a refrigerated packaging solution appears to be a cost effective solution which optimizes the TCO – Total Cost of Ownership, a key factor is to take into account in the cost-effectiveness calculation of the packaging solution: the logistical circuit.

Let’s take a look at 3 reutilisation circuits: the pharmaceutical laboratory orders the delivery of its temperature-controlled products through its partner to a pharmaceutical Hub.

Reutilisation circuit of a pharmaceutical insulated box

Logistical circuit 1: The insulated solution is recovered by the logistician, then inspected and put back into the distribution network.

Logistical circuit 2: The packaging solution is recovered internally or disposed of.

Logistical circuit 3: The insulated packaging solution is sent back to the supplier.

Cost of transport for 3 different cold chain packaging solutions

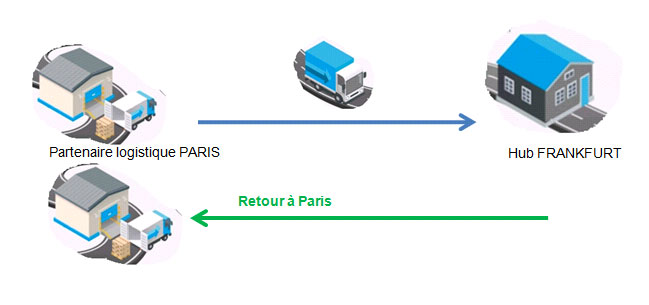

Let’s compare the cost of transport of 3 packaging solutions (qualified packaging solutions at +2/+8°C for a duration of 120 hours) with a temperature-controlled shipment from Paris –Frankfurt, by lorry.

| Solution | Use | Ext. Vol. (L) |

Net Vol. (L) |

Weight (Kg) |

Weight/Vol. Ratio |

Price packaging solution |

Price transport Paris-Frankfurt |

|

|---|---|---|---|---|---|---|---|---|

| A | Multi-configuration | Single | 220 | 72 | 18 | 33% | €85 | €32.52 |

| B | Mono-configuration | Single | 166 | 56 | 21 | 33% | €300 | €38.24 |

| C | Mono-configuration | Reusable | 141 | 56 | 25 | 42% | > €500 | €38.24 |

It should be noted that with a payload of 72 litres, solution A will cost €32.52 versus €38.24 for solution C. Insulated packaging solution C is therefore 15% more expensive while its net volume is 20% less. However, it offers more usable space (42% versus 33%), which allows a greater volume of temperature-controlled products to be shipped in a single journey.

Total cost of reuse for 3 different insulated packaging solutions

Let’s assume that in 100% of cases, the insulated packaging solution is sent back to the provider to be reintegrated into the distribution network. The packaging solution is systematically inspected by the receiving quality department. The cost of quality control is estimated at 20€ - an amount corresponding to the time spent by the operator to inspect the packaging solution, or, the cost of inspection by an infrared system or other system chosen by the packaging solution provider.

The cost of storing the boxes is not taken into account in this case.

The cost of reusing the insulated packaging solution takes into account:

- the cost of shipping the packaging solution from Paris to Frankfurt by lorry;

- the cost of repatriating the insulated box from Frankfurt to Paris by lorry;

- quality control costs.

Calculation of the total logistical cost by insulated packaging solution:

Solution A: single use - multi-configuration

Shipment 1: purchase price + transport, equals € 117.52.

Shipment 2: purchase price + transport, equals € 117.52.

Solution B: single use – Mono-configuration

Shipment 1: purchase price (€ 300) + transport (€ 38.24) + return transport (€ 49.71) + inspection (€ 20) = € 407.95.

Shipment 2: transport (€ 38.24) + return transport (€ 45.88) + control (€ 20) = € 104.12.

Shipment 3: transport (€ 38.24) + return transport (€ 45.88) + control (€ 20) = € 104.12.

Solution C: reusable – Mono-configuration

Shipment 1 = purchase price (€ 500) + transport (€ 38.24) + return transport (€ 49.71) + inspection (€ 20) = € 607.95.

Shipment 2 = transport (€ 38.24) + return transport (€ 49.71) + inspection (€ 20) = € 107.95.

Shipment 3 = transport (€ 38.24) + return transport (€ 49.71) + inspection (€ 20) = € 107.95.

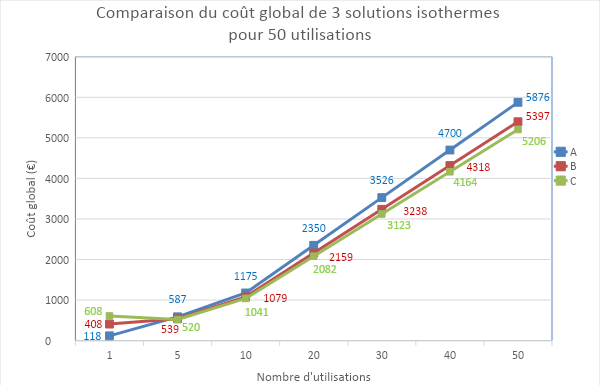

Total cost for 50 uses of the insulated packaging solution

Comparison of total logistical costs (insulated packaging solution and transport) of 2 single-use insulated boxes and 1 reusable packaging solution for 50 uses

After 50 uses,

- Solution A comes to € 5 876

- Solution B comes to a total cost of 408 + 5 397 = € 5 805

- Solution C comes to a total cost of 608 + 5 206 = € 5 814

In this example, the total cost of the so-called reusable and single-use insulated packaging solutions is essentially the same.

But let’s not forget that there is the basic assumption that the insulated box is returned in 100% of cases, with possible reuse. In reality, insulated packaging solutions are not all returned and are not all reusable 50 times.

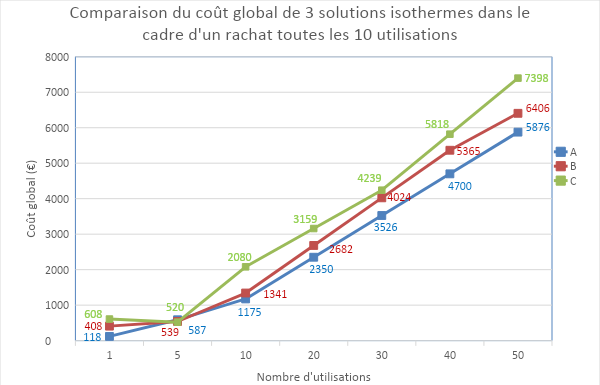

Let us therefore calculate the total cost for repurchasing an insulated packaging solution every 10 uses.

Comparison of total logistical costs (insulated packaging solution and transport) of 2 single-use insulated boxes and 1 reusable packaging solution repurchased every 10 uses

Based on the assumptions made, we see that after 5 uses, the total cost of a single-use insulated packaging solution is more cost-effective.

However, be sure to remain cautious of the reported values. All logistics are different and a preliminary study should be carried out to choose the most cost-effective logistical solution in terms of TCO for your insulated packaging solutions, and of course the most secure.

Our cold chain experts can assist you to identify the most suitable insulated packaging solution for your cold chain logistics, contact us!