Thematic studies

News

Case studies

"Zero Excursion", fiction or reality?

The cold chain of heat temperature-sensitive health products (vaccines, medicines, biological samples…) is subject to strict regulation. The relevant actors look for solutions allowing to meet regulatory requirements and product specifications. For them, it involves selecting a solution that secures the product temperature but at a lower cost and without preparation constraints. Based on the analysis of thousands of actual temperature recordings, this study presents the main causes of temperature excursions and the actions to be implemented to avoid them.

« Zero excursion » is it a realistic and achievable target or a pious hope? What are the main causes of excursions? How to avoid them?

Temperature range

The most temperature ranges concerned by the excursions are +2/+8 °C and +15/+25 °C. For these applications, the solution must meet the required high and low limits. The frozen products are less concerned because the external temperature is always higher than the high limit. We just have to use a PCM with a melting temperature below the high limit and close to the low limit of the range.

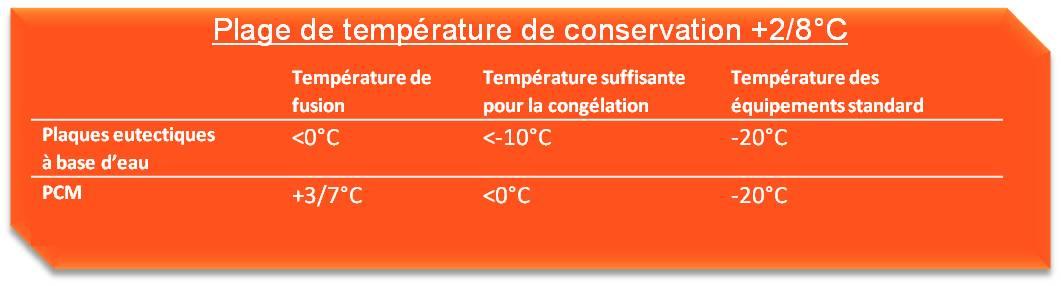

Figure 1 - When and How to use a water based eutectic plates versus PCMs ?

Water based eutectic plates or PCMs?

The material used for the thermal storage (clod or heat) is the first determining parameter for excursions, in particular its melting temperature.

The water based eutectic solutions offers a high latent heat at a temperature lower or equal to 0 °C for a reduced cost. This solution is used for products to be maintained between +2 °C and +8 °C, with a dual or even triple configuration (packout) summer, winter and mid-season. The difficulty remains in the management of mid-seasons and the switch from one configuration to another. It’s also used with a single configuration for logistics circuits characterised by a hot profile with possible very short segments. In some cases, plates stabilised at +5 °C are used as a separation between the frozen plates and the products in order to reduce the risk of excursions below +2 °C.

PCMs are used for the products +2/+8 °C, +15/+25 °C and for other temperature ranges above 0 °C. The PCMs offer a latent heat lower than that of water at a temperature adapted to the products for a higher cost. This solution can be used with a dual configuration summer and winter or with single configuration. In universal configuration, the PCM plates are usually frozen then increase their temperature and placed around products (on all sex sides). In some cases, they are stabilised at a temperature close de +5 °C without reaching freezing. In both cases, the solution is oversized because the thermal storage is reduced.

By choosing an adapted melting temperature, water based eutectic solutions allow to maintain frozen products with single configuration. Dry ice allows also to maintain frozen products at very low temperatures.

Figure 2 – Comparison of preparation characteristics of water baser eutectic plates versus PCMs for +2/+8 °C and +15/+25 °C.

Can we avoid freezing of PCMs or water based solutions?

The thermal storage capacity is mainly ensured by the latent phase. Whatever the material, the sensitive phase cannot provide sufficient performance to meet real needs. With a melting temperature of 0 °C, water baser eutectic solutions can only be correctly frozen below -10 °C. The PCMs used for products +2/+8 °C, have melting temperatures between +3 °C and +7 °C. To solidify these PCMs, you must use a specific room set at temperature close to 0 °C or use standard freezers operating between -30 °C and -18 °C and then you have to increase their temperature. You can stabilise these PCMs between +2 °C and +5 °C but their performance will be reduced.

Analysis of temperature excursions

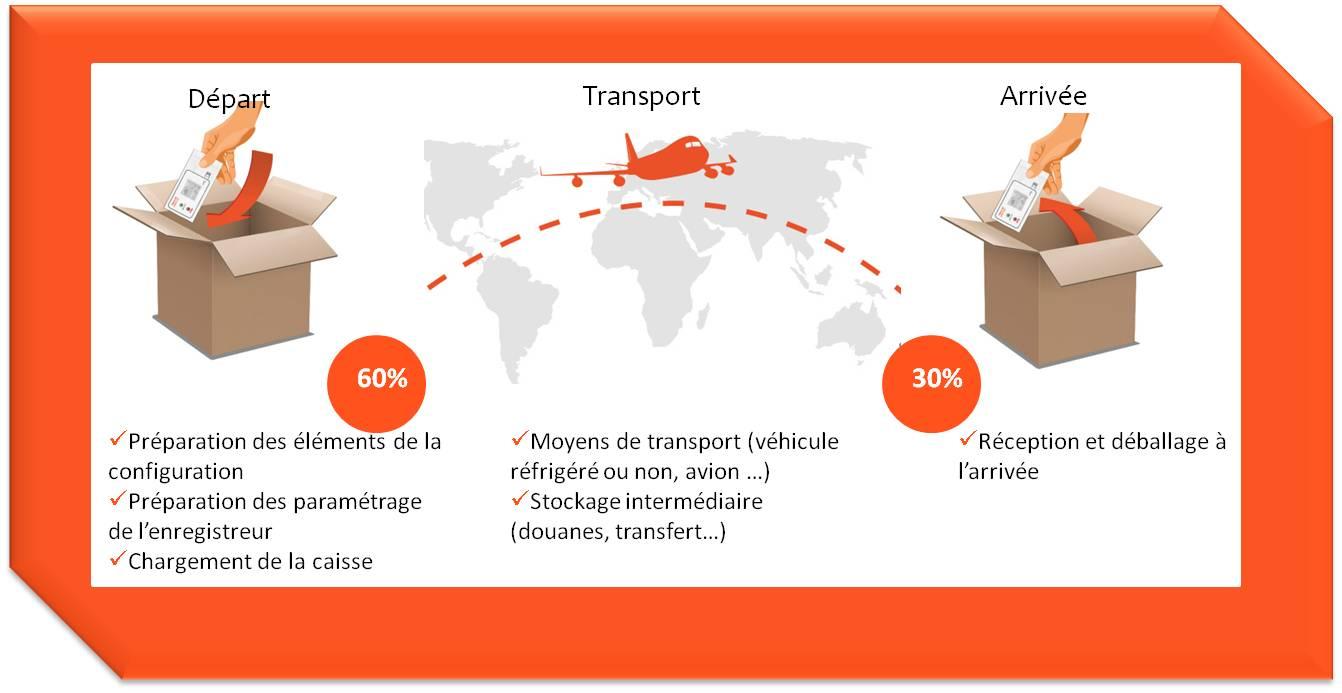

Figure 3 - Parameters that cause excursions, Distribution of recorded excursions in %

Temperature excursions and their position in the logistics circuit are determined, allowing the identification of the logistics steps and the associated environment. In a continuous improvement approach, the analysis allowed to evaluate the compatibility of the qualified configuration with the actual profiles and to propose suitable solutions. Excursions are classified according to their nature (below +2 °C or above +8 °C) and according the logistic step: at the beginning, during transport and at the arrival.

The following parameters may be the cause of excursions:

- Preparation of the configuration elements

- Preparation and et configuration of the logger

- Loading of the insulated packaging

- Means of transport (refrigerated vehicle or not, aircraft...)

- Intermediate storage (customs, transfer…)

- Reception and unpacking at the arrival

60% of excursions are recorded at the beginning and 30% at the arrival, that is to say 90% of cases are due to preparation or unpacking errors and they are potentially avoidable.

Excursions below +2 °C are recorded for the configuration using frozen eutectic plates. They occur initially when the boxes are stored in the cold room after loading and in some cases in the middle of the profile as a result of an unplanned intermediate storage at +5 °C or a transport in a refrigerated truck.

Excursions above +8 °C are mainly recorded for the configuration using eutectic plates or PCMs stabilized at +5 °C. This configuration requires appropriate preparation because the cold reserve is very low and any excess of +8 °C at the beginning causes the same type of excursions in the middle and at the end of the profile.

Statistical analysis of actual readings shows that actual temperature profiles are more moderate than those required in qualification tests. In most cases the hot or cold profiles required for qualification are more binding, which can complicate the solution and cause excursions. The majority of international shipments use one step storage or transport at +5°C at least and the duration is not controlled. If the box is qualified to be stored and transported in an ambient environment (between +15 °C and +25 °C), the intermediate storage at +5 °C or the use of a refrigerated truck cause excursions below +2 °C. In some configurations, it is the opposite that occurs when the logistics steps planned at +5 °C are not respected. For the same destination, the position of hottest and coldest segments changes over time in the profiles. They may be in the same position of the qualification profiles or in advance or late.

The majority of the alarms at the beginning or at the arrival are false excursions recorded at loading hot recorders or during unpacking by removing them without stopping the recording. In many cases, registration is stopped several days or even several weeks after the arrival.

For better control

The cold chain logistics must be controlled as a whole, from the establishment of specifications to the use of the solution through the design and qualification. Responsibilities and acceptance criteria must be defined. This comprehensive approach optimises performance and the total logistics cost (TCO).

Design and qualification

Specifications for designing or choosing a temperature-controlled box must take into account product temperature requirements and accepted tolerances based on stability tests. The logistics steps and associated durations must be identified (preparation, storage, loading, transport, intermediate storage, customs, transfer and delivery area ...). A risk analysis taking into account all the parameters of the shipment must be established.

Departure of the expedition

The means used for thermal storage (PCM or water-based solution) must be prepared under the required conditions and according to the validated procedure. The loading time must be reduced. Frozen plates (PCM or water-based) must be loaded first, then liquid ones and finally products. For +2/+8 °C products, storage and shipping at +5 °C are favoured for configurations using unfrozen plates. The reverse must be applied for configurations with frozen plates. The data loggers must be conditioned to the temperature of the products and parameterized in a suitable way.

During the transport

The actual logistics circuit must be identified and the configuration must be adapted. Storage or transport steps at +5 °C (cold room or refrigerated truck) must be respected. The logistics partners and all actors need to be trained and informed.

Arrival at destination

A procedure for unpacking and stopping the loggers must be established and respected to avoid false excursions and false alarms. Stakeholders must be trained and informed.

An insulated box equipped with a thermal storage means is a solution designed for predefined temperature profiles. The use of PCMs and over-sizing of the solution reduce temperature excursions but cannot eradicate them. To reach zero excursion, the logistics circuit must be controlled within predefined limits of temperature and duration. These conditions must be respected to ensure the reproducibility of the results. The phenomenon of temperature excursions goes beyond the sole responsibility of the insulated box to the respect of the established operating procedure and the control of the logistics steps. Logistics hazards are the main cause of excursions. The cold chain must be optimized as in its entirety: specifications, design of the box, pre-qualification, preparation, transport, reception. All actors in the chain need to be trained and informed to respect good practices of use of the cold chain packaging solution. They must also be involved in a continual improvement process.