Thematic studies

News

Case studies

Thermochemical Sorption: A Solution for the Temperature-controlled Transport

By Abbes KACIMI, Aleix PUBILL, David TADIOTTO

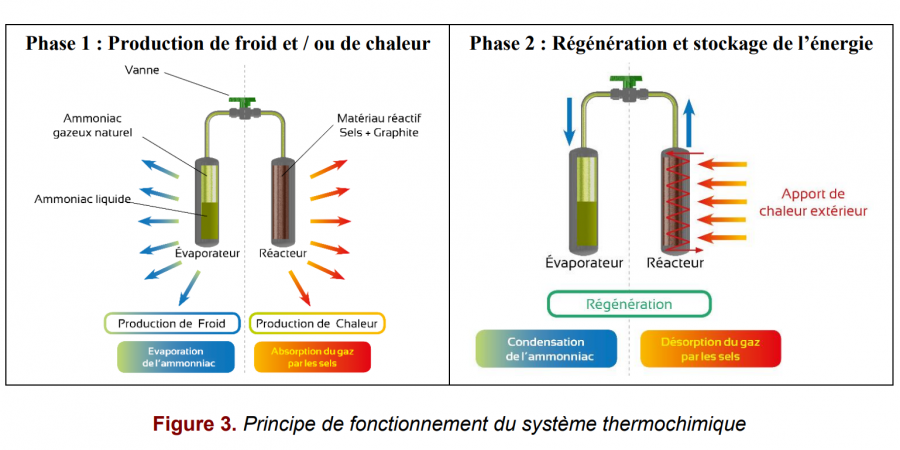

The thermochemical storage based on the solid-gas sorption process is used in a temperature-controlled transport container. The principle is based on the coupling of a liquid-to-gas phase change of a natural fluid (ammonia) and a reversible reaction between this gas and a reactive solid. It allows producing a controlled refrigeration effect, offering a standalone solution (container) for transport and maintaining the cold chain requirements. This article presents the principle of liquid/gas sorption and the results of the thermal performance tests carried out on standalone thermal containers for different temperature ranges. This solution allows to transport heat-sensitive products between +2 °C and +8 °C or between 0 °C and +4 °C or below -18 °C. Depending on the outdoor temperature profile, the required temperature, the door openings, and the products' thermal inertia, the container's autonomy varies from 8 to 48 hours.

Discover the full scientific paper here.

The thermochemical process based on solid-gas sorption enables thermal energy to be stored and cold to be produced later and used as and when required.

Isothermal containers fitted with this system help to secure the cold chain. Depending on reactor size, insulation, and outside temperature, this solution can maintain heat-sensitive products at different temperature ranges. These self-contained, temperature-controlled containers combine the advantages of static solutions with eutectic plates or phase-change materials (PCMs) with those of dynamic solutions with refrigeration units. They

can be easily transported or integrated into standard vehicles. Using ammonia as a working fluid offers the advantage of using a well-known natural refrigerant and reduces greenhouse gas emissions and environmental impact. After decades of research, this technology can now be integrated into cold chain logistics, industry, space, and automotive sectors.